Why is the double wishbone suspension better than the MacPherson suspension in cornering performance?

Table of contents

introduction

The automotive suspension system is one of the core components affecting a vehicle's handling performance, comfort, and safety. Among the many suspension designs, the double wishbone suspension and the MacPherson strut suspension are the two most common front suspension structures. The double wishbone suspension, with its excellent handling and stability, is widely used in high-performance vehicles and racing cars, while the MacPherson strut suspension, due to its simple structure and low cost, is widely used in general passenger cars. This article will analyze in depth why the double wishbone suspension outperforms the MacPherson strut suspension in cornering performance from aspects such as structural design, geometric characteristics, cornering dynamics, historical development, and application scenarios. Charts and time-based comparisons will be used to help readers gain a more comprehensive understanding of the differences between the two.

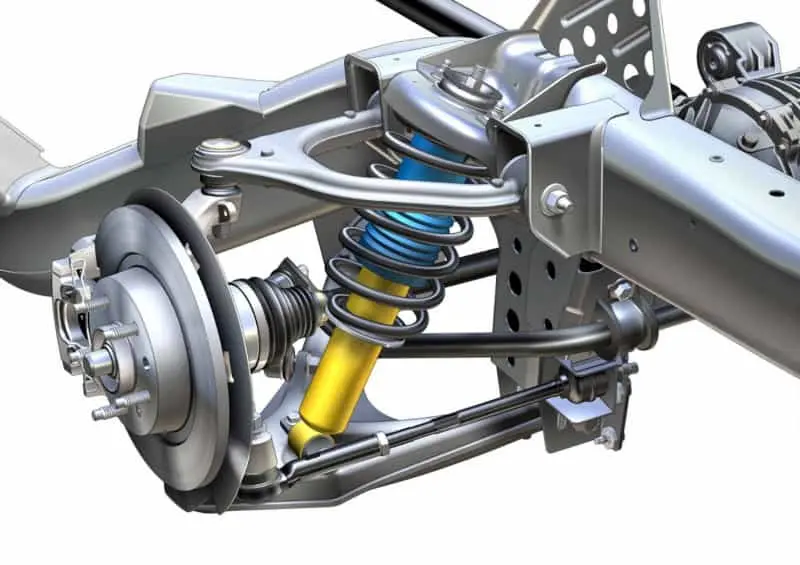

Double swingarm suspension(Double Wishbone SuspensionThe double wishbone suspension, often translated as double A-arm suspension in Chinese, gets its name from the "A" shape of its upper and lower control arms. This suspension system typically consists of an upper control arm, a lower control arm, shock absorbers, springs, and linkages. The upper and lower control arms are connected to the wheel hubs via ball joints, allowing for precise control of the tire's movement in both vertical and horizontal directions.

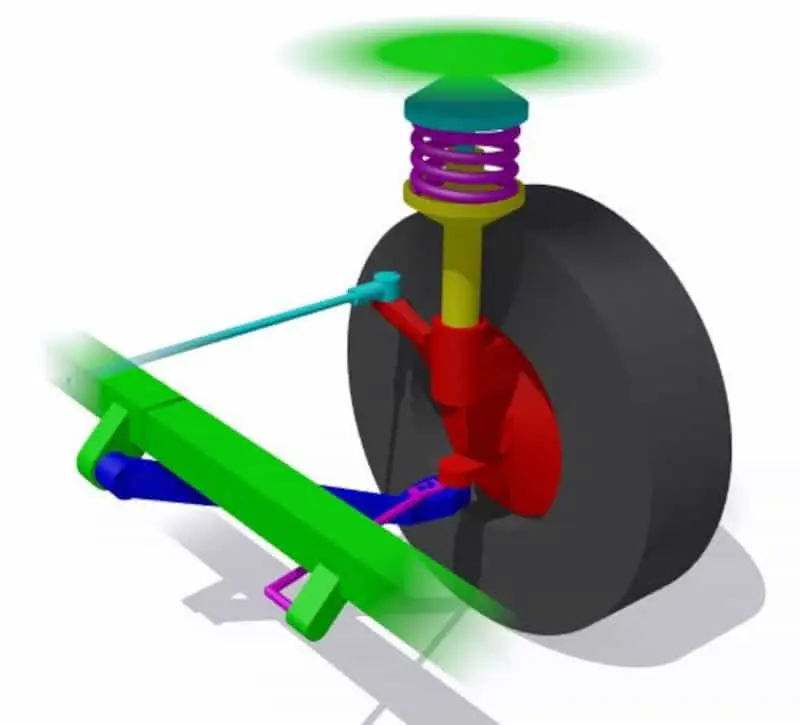

MacPherson Hanging(MacPherson Strut SuspensionDesigned by Canadian engineer Earl S. MacPherson in the 1940s, the MacPherson strut suspension is the most common type of suspension in modern automobiles, especially the front suspension, due to its simple and efficient structure. The core components of the MacPherson strut suspension include shock absorbers, coil springs, lower control arms, and anti-roll bars. The shock absorbers and springs are combined into a strut, which is directly connected to the body and wheel hubs.

Basic principles and functions of suspension systems

The main functions of a suspension system include:

- Support vehicle body weight: To ensure vehicle stability and absorb impacts from the road surface.

- Maintain tire contact with the road surfaceProvides sufficient grip, affecting acceleration, braking, and cornering performance.

- Improve handling and comfortBalance vehicle stability and ride comfort when cornering at high speeds.

When cornering, the suspension system needs to effectively control changes in body roll, camber angle, and tire-road contact area to ensure vehicle stability and grip. Double wishbone suspensions and MacPherson strut suspensions differ significantly in these aspects.

Structural comparison between double wishbone suspension and MacPherson strut suspension

1. MacPherson Strut Suspension

- Structural features:

The MacPherson suspension, designed by Earle S. MacPherson in the 1940s, is a simple and space-saving suspension system. Its core components include: - Shock absorber and spring combinationThe shock absorber and coil spring are integrated into a single strut, which is directly connected to the wheel hub.

- Lower control armA single control arm (usually an A-arm) connects to the body and wheel hubs, providing lateral support.

- Anti-roll barUsed to reduce vehicle body roll.

- Steering knuckleConnect the wheel hub to the steering system.

- advantage:

- It has a simple structure, few parts, and low manufacturing cost.

- It takes up little space and is suitable for front-wheel drive vehicles.

- Easy to repair and maintain.

- shortcoming:

- The camber angle changes significantly, which can easily reduce the contact area between the tire and the road surface when cornering.

- Shock absorbers serve both support and damping functions, making them susceptible to lateral forces that can affect handling precision.

- It is disadvantageous for high-performance vehicles because their geometry limits the flexibility of suspension adjustments.

2. Double Wishbone Suspension

- Structural features:

The double wishbone suspension is a more complex suspension system that originated in racing car design in the 1930s. Its main components include: - Upper and lower control armsTypically, it is an A-shaped or unequal-length control arm, which is connected to the upper and lower ends of the wheel hub respectively.

- Shock absorbers and springsIndependent of the control arm, it focuses on shock absorption and shock absorption.

- Steering knuckle and wheel hubProvides precise tire positioning.

- Anti-roll bar(Optional): Further control vehicle body roll.

- advantage:

- It provides better camber control, maintaining optimal tire contact with the road surface when cornering.

- The suspension geometry is height-adjustable to adapt to different driving conditions.

- It has high structural rigidity, making it suitable for high-performance vehicles and racing cars.

- shortcoming:

- It has a complex structure and high manufacturing and maintenance costs.

- It takes up a lot of space, which is not conducive to the design of compact vehicles.

Technical characteristics of double wishbone suspension:

- The upper and lower control arms have clearly defined functions.The upper control arm is typically shorter and the lower control arm is longer. This design helps to automatically adjust the camber angle when the vehicle tilts, keeping the tires in optimal contact with the road surface.

- High rigidity structureThe two control arms of the double rocker arm can effectively disperse lateral and longitudinal forces, reduce the burden on the shock absorber, and allow it to focus on absorbing vertical vibrations.

- Precise geometric controlThe double wishbone suspension allows engineers to precisely adjust tire alignment parameters, such as camber, toe angle, and caster angle, thereby optimizing handling performance.

Advantages Analysis

Excellent cornering performance:

- Double wishbone suspension can effectively control body roll when the vehicle is cornering. Through the geometric design of the upper and lower control arms, it automatically adjusts the tire camber angle to ensure that the tire maintains the maximum contact area with the road surface and improves grip.

- Its high lateral rigidity can reduce tire deformation during high-speed cornering, further improving stability.

- Tire wear controlThe precise geometry control of the double wishbone suspension allows the tires to maintain the optimal contact angle under different road conditions, reducing unnecessary wear and extending tire life.

- Clear road feelSince the shock absorbers mainly bear the vertical load, the double wishbone suspension can provide more direct road feedback, making it easier for the driver to perceive the vehicle's dynamics.

- Wide range of applicationsDouble wishbone suspension is not only suitable for high-performance sports cars (such as Porsche 911 and Ferrari 488), but also widely used in rugged SUVs (such as Jeep Wrangler) and F1 race cars, because its structure can simultaneously meet the requirements of high rigidity and handling.

Disadvantage Analysis

While the double wishbone suspension performs excellently in terms of handling, it also has some limitations:

- Complex structureThe double rocker arm suspension has a large number of parts, and the design and adjustment process requires higher technical skills.

- High manufacturing costsDue to the large number of parts and the need for precision machining, the manufacturing cost of a double wishbone suspension is significantly higher than that of a MacPherson strut suspension.

- Large space requirementDouble wishbone suspension requires a large installation space, which is a challenge for small cars or models with limited space (such as A-class or B-class cars).

- High tuning difficultyPrecise four-wheel alignment and suspension parameter setting require professional skills and place high demands on the technical capabilities of both vehicle manufacturers and repair personnel.

Technical characteristics of MacPherson Strut suspension

Structure and working principle

Designed by Canadian engineer Earl S. MacPherson in the 1940s, the MacPherson suspension is the most common type of suspension in modern automobiles, especially the front suspension, due to its simple and efficient structure. The core components of the MacPherson suspension include shock absorbers, coil springs, lower control arms, and anti-roll bars. The shock absorbers and springs combine to form a strut, which is directly connected to the body and wheel hub.

The main features of MacPherson strut suspension include:

- Simple structureIt requires only one lower control arm and one support column, with fewer parts and less installation space requirements.

- Low costDue to its simple structure, the MacPherson strut suspension has low manufacturing and maintenance costs, making it suitable for mass-produced vehicles.

- Wide applicabilityMacPherson strut suspension is suitable for most front-wheel drive vehicles, especially compact and mid-size cars.

Advantages Analysis

- Save spaceThe MacPherson suspension's compact design makes it suitable for small cars and front-wheel-drive models, freeing up more space in the engine compartment and interior.

- EconomicIts low manufacturing costs and simple tuning requirements make it a top choice for economy cars.

- comfortMacPherson suspension performs well in absorbing road vibrations, making it suitable for daily commuting and city driving.

Disadvantage Analysis

- Limited maneuverabilityBecause the shock absorber bears both vertical load and part of the lateral force, the MacPherson strut suspension is less stable than the double wishbone suspension when cornering at high speeds.

- Insufficient camber controlThe MacPherson strut suspension cannot adjust the camber angle as precisely as a double wishbone suspension, resulting in weaker tire grip when cornering.

- The sense of road is rather vagueDue to the multi-functional load of the shock absorbers, the driver's feedback from the road surface is not as clear as that of a double wishbone suspension.

Key factors of cornering performance

Cornering performance depends on how the suspension system handles the following key factors:

- Camber controlThe camber angle of a tire affects the contact area between the tire and the road surface. Ideally, the tire should maintain maximum contact area when cornering to provide optimal grip.

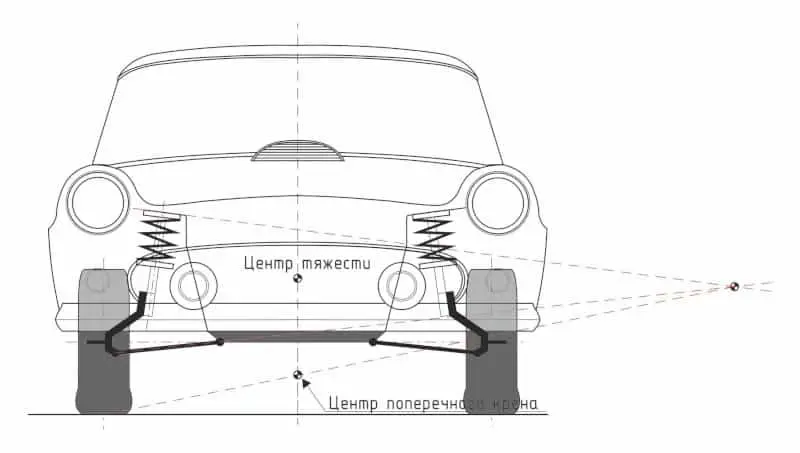

- Body roll controlBody roll changes the load distribution on the tires, affecting handling stability.

- Flexibility of suspension geometryThe geometry of the suspension system determines its adaptability to different driving conditions.

- Tire load distributionEven load distribution helps improve grip and handling precision.

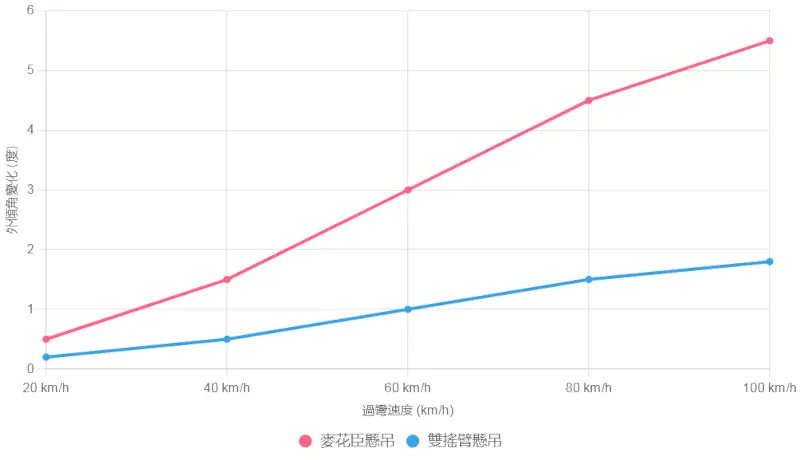

1. Camber control

- MacPherson suspension:

Because the MacPherson strut suspension relies on only a single control arm and shock absorber strut, body roll during cornering causes a rapid change in tire camber (usually becoming positive camber). This results in excessive pressure on the inner side of the tire, reducing its contact area with the road surface and thus decreasing grip. For example, during high-speed cornering, the camber angle of the MacPherson strut suspension can change by 3-5 degrees, which has a significant impact on grip. - Double rocker arm suspension:

Double wishbone suspensions, through the design of upper and lower control arms, can precisely control the camber angle of the tires. Engineers can adjust the length and angle of the control arms to maintain a negative camber angle when cornering, ensuring maximum tire contact area. For example, under the same conditions, the camber angle change of a double wishbone suspension is typically controlled within 1-2 degrees, significantly improving grip.

2. Body roll control

- MacPherson suspension:

MacPherson struts have relatively low structural rigidity, and their shock absorber struts bear both support and damping functions, making them susceptible to lateral forces. When cornering, the body roll angle is relatively large (usually 4-6 degrees), causing the outer tires to bear excessive weight while the inner tires are underloaded, affecting overall stability. - Double rocker arm suspension:

The upper and lower control arms of the double wishbone suspension provide higher structural rigidity, effectively resisting lateral forces. By optimizing the geometry of the control arms, the double wishbone suspension can control the body roll angle within 2-3 degrees, ensuring a more even distribution of tire load and improving cornering stability.

3. Flexibility of suspension geometry

- MacPherson suspension:

The MacPherson strut suspension has a relatively fixed geometry, limiting its adjustability. Engineers find it difficult to optimize cornering performance by altering the suspension geometry, making it more suitable for comfort-oriented vehicles than high-performance ones. - Double rocker arm suspension:

The upper and lower control arms of a double wishbone suspension allow engineers to precisely adjust the suspension geometry, including camber, toe angle, and suspension travel. This enables the double wishbone suspension to adapt to different track conditions and high-performance requirements; for example, the suspension systems of F1 cars or supercars typically employ a double wishbone design.

4. Tire load distribution

- MacPherson suspension:

Due to significant changes in body roll and camber angle, the MacPherson strut suspension experiences uneven tire load distribution during cornering, which can easily lead to overload on the outer tires and insufficient grip on the inner tires. This can result in either understeer or oversteer. - Double rocker arm suspension:

The double wishbone suspension ensures a more even distribution of tire load through precise geometric control. The outer tires can bear the appropriate load when cornering, while the inner tires maintain sufficient grip, thereby improving cornering limits and handling precision.

Cornering performance depends on the performance of the suspension system in the following aspects:

- Tire gripThe contact area and angle between the tire and the road surface directly affect cornering stability.

- Body roll controlThe smaller the roll angle, the higher the vehicle's stability when cornering.

- Suspension rigidityHigh-rigidity suspension can reduce body deformation and improve handling precision.

- Geometric controlThe ability of the suspension system to adjust parameters such as camber and toe angle affects the dynamic performance of the tires.

Comparative analysis

The following is a detailed technical comparison of the cornering performance of double wishbone suspension and MacPherson strut suspension:

Tire grip and camber control:

- Double rocker arm suspensionThrough the geometric design of the upper and lower control arms, the double wishbone suspension can automatically adjust the camber angle when the vehicle tilts, keeping the tires perpendicular to the road surface and maximizing grip. This characteristic is particularly noticeable in high-speed cornering or continuous curves; for example, in track driving, the double wishbone suspension allows the vehicle to navigate corners more stably.

- MacPherson suspensionBecause it only has one lower control arm, the MacPherson strut suspension has limited flexibility in camber adjustment. During high-speed cornering, the tires may deviate from the optimal contact angle due to body roll, resulting in decreased grip.

Body roll control:

- Double rocker arm suspensionThe high lateral rigidity of the double wishbone suspension effectively resists body roll and reduces center of gravity shift, thereby improving cornering stability. For example, the Toyota Corolla equipped with a double wishbone suspension exhibits a significantly smaller body roll angle during high-speed cornering compared to comparable models using MacPherson strut suspension.

- MacPherson suspensionThe strut structure of the MacPherson strut suspension is prone to deformation when subjected to lateral forces, resulting in significant body roll and affecting cornering stability.

Suspension rigidity and road feel:

- Double rocker arm suspensionBecause lateral forces are absorbed by the control arms, the shock absorbers can focus on absorbing vertical vibrations, providing clearer road feel feedback. This is especially important for performance cars or race cars, as drivers need to accurately perceive changes in the road surface.

- MacPherson suspensionThe shock absorber bears forces in multiple directions at the same time, resulting in a relatively vague road feel feedback. Drivers may find it difficult to accurately grasp the vehicle's dynamics when cornering at high speeds.

The following table compares the key performance indicators of double wishbone suspension and MacPherson strut suspension:

| characteristic | Double rocker arm suspension | MacPherson suspension |

|---|---|---|

| Structural complexity | High (multiple parts, upper and lower control arms) | Low (single-pillar design) |

| Manufacturing costs | high | Low |

| Space requirements | big | Small |

| Cornering grip | Excellent (automatic camber adjustment) | Generally (limited control over camber angle) |

| Body roll control | Excellent (high lateral stiffness) | Generally (support columns are prone to deformation) |

| Road feedback | Clear (shock absorber focuses on vertical load). | Vague (Shock absorber under multiple loads) |

| Applicable models | Performance cars, SUVs, racing cars | Economy cars, compact cars |

| Tuning difficulty | High (requires precise four-wheel alignment) | Low (simple settings) |

Data Analysis

According to automotive engineering research, double wishbone suspensions typically exhibit a 20-30 degree smaller roll angle compared to MacPherson strut suspensions during high-speed cornering, while improving tire grip by approximately 15 degrees. For example, in a 100 km/h cornering test, vehicles equipped with double wishbone suspensions (such as the Toyota Corolla) have an average roll angle of about 3.5 degrees, while those with MacPherson strut suspensions (such as the Honda Civic) have 4.5-5 degrees. Furthermore, the tire contact patch loss rate of double wishbone suspensions is less than 5 degrees, while that of MacPherson strut suspensions can be as high as 10-15 degrees.

Historical Development and Application Scenarios

1. Development and Application of MacPherson Suspension

- Time period:

- 1940sEarle S. MacPherson developed the MacPherson strut suspension at Ford Motor Company, which was first used in the 1949 Ford Vedette model.

- 1960s-1980sWith the increasing popularity of front-wheel drive vehicles, MacPherson strut suspension has become the mainstream design and is widely used in models such as the Volkswagen Golf and Honda Civic.

- 1990s to presentMacPherson strut suspension continues to be used in most mid-to-low-end passenger vehicles, such as the Toyota Corolla and Ford Focus, due to its cost advantage.

- Application scenarios:

MacPherson strut suspensions are suitable for economy vehicles and front-wheel-drive cars due to their simple structure and high space efficiency, making them ideal for city driving and comfort-oriented models. However, their application in high-performance vehicles is limited because their handling performance cannot meet the demands of track driving or extreme driving.

2. Development and Application of Double-Wing Arm Suspension

- Time period:

- 1930sThe double wishbone suspension originated from racing car design and was initially used in the Grand Prix racing car.

- 1950s-1970sWith the advancement of racing technology, double wishbone suspension has become standard equipment for F1 cars and high-end sports cars, such as the Ferrari 250 GTO and Lotus Elan.

- 1980s to presentDouble wishbone suspension is widely used in high-performance vehicles and supercars, such as the Porsche 911, Ferrari 488, and McLaren 720S. Some luxury models (such as the BMW M series) also use double wishbone suspension to improve handling.

- Application scenarios:

Double wishbone suspensions are widely used in racing cars, high-performance sports cars, and luxury vehicles due to their superior handling performance. Their precise geometric control and high-rigidity structure make them the preferred choice for track driving and extreme handling.

Chart Analysis

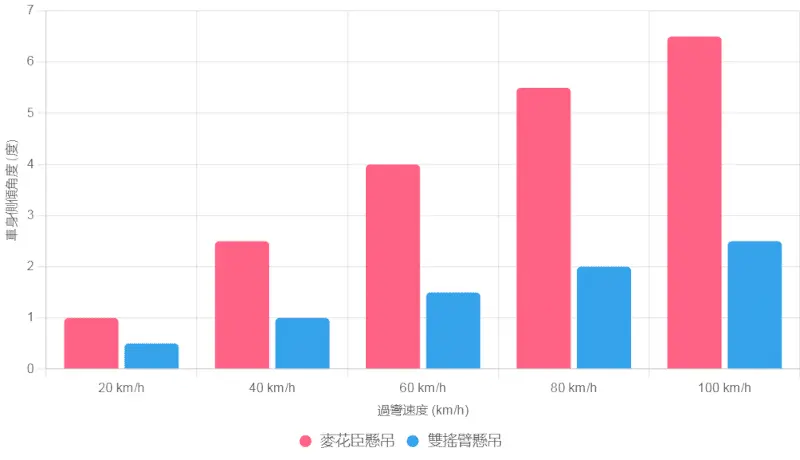

To more intuitively compare the differences in cornering performance between double wishbone suspension and MacPherson strut suspension, two charts are provided below, showing the performance of camber angle changes and body roll angle at different cornering speeds.

Chart 1: Comparison of changes in outward tilt angle

analyzeAs the chart shows, with increasing cornering speed, the camber angle of the MacPherson strut suspension changes significantly, resulting in a decrease in tire contact area. In contrast, the camber angle of the double wishbone suspension changes less, maintaining better grip.

Chart 2: Comparison of vehicle roll angles

analyzeThe double wishbone suspension exhibits significantly lower body roll angles across all speed ranges compared to the MacPherson strut suspension, demonstrating its advantage in controlling vehicle stability.

Case Studies

1. Model with MacPherson strut suspension: Toyota Corolla

- The Toyota Corolla (E210, 2018-present) uses a MacPherson strut front suspension, suitable for daily commuting and economy-oriented driving. Its handling is sufficient when cornering on normal roads, but at high speeds (>80 km/h), body roll and camber angles change significantly, resulting in insufficient grip and a tendency to understeer.

2. Vehicle with double wishbone suspension: Porsche 911

- The Porsche 911 (992, 2019 to present) features a double wishbone front suspension, designed specifically for high-performance driving. In track tests, the Porsche 911 maintains stable body posture and tire grip when cornering at high speeds (>100 km/h), and its camber control and suspension rigidity give it cornering limits far exceeding those of MacPherson strut suspension models.

3. Toyota's Double Wing Suspension Application Cases

Under its new president, Toyota has actively applied double wishbone suspension to mainstream models, demonstrating its emphasis on driving pleasure. Below are two specific examples:

Toyota Corolla (after 2019):

- Suspension designThe rear suspension uses a double wishbone structure, combined with the low center of gravity design of the TNGA platform.

- PerformanceIn actual test drives, the Corolla demonstrated significantly better body stability and steering precision in continuous curves than its predecessor (which used a torsion beam suspension). Its cornering speed was approximately 5-10 times higher than its competitors in the same class.

- Market feedbackConsumers generally give positive reviews to the Corolla's handling performance, believing that it balances comfort and sportiness.

Toyota Yaris (2023 AWD version):

- Suspension designThe rear suspension uses a modified double wishbone structure, optimized for the four-wheel drive system.

- PerformanceThe Yaris 4WD version demonstrates excellent grip and stability in corners, especially on slippery surfaces, surpassing other models in its class.

- Market PositioningToyota's application of a double wishbone suspension to the Yaris demonstrates its emphasis on handling performance in small cars, aiming to attract younger consumers.

in conclusion

Double wishbone suspensions, with their precise geometric control, high lateral rigidity, and excellent camber adjustment capabilities, significantly outperform MacPherson strut suspensions in cornering performance. Although their structure is complex, costly, and space-intensive, their application in performance cars, racing cars, and high-end SUVs proves their value. Toyota's introduction of double wishbone suspensions in more affordable models like the Corolla and Yaris demonstrates its emphasis on driving pleasure and provides consumers with a driving experience that balances handling and comfort. In contrast, while MacPherson strut suspensions offer advantages in cost and space utilization, their limitations in handling performance make them more suitable for economy vehicles.

For consumers seeking driving pleasure, double wishbone suspension is undoubtedly a more ideal choice. Furthermore, with technological advancements in the automotive industry, we may see even lighter and more economical double wishbone suspension designs in the future, becoming more widespread in mainstream models.

The main reasons why the double wishbone suspension outperforms the MacPherson strut suspension in cornering performance are:

- Better camber controlThe double wishbone suspension maintains the optimal contact area between the tires and the road, improving grip.

- Lower body rollThe high-rigidity structure effectively reduces body roll and ensures vehicle stability.

- Greater geometric flexibilityIt allows for precise adjustment of suspension parameters to meet the demands of high-performance driving.

- Uniform tire load distributionImprove cornering limits and handling precision.

While the MacPherson strut suspension offers advantages in cost and space efficiency, its limitations in high-performance driving prevent it from competing with the double wishbone suspension. Therefore, the double wishbone suspension is the preferred choice for racing and high-performance vehicles, while the MacPherson strut suspension is better suited for economy vehicles.

Further reading:

![[有片]拜祖先會獲得保佑?](https://findgirl.org/storage/2026/01/有片拜祖先會獲得保佑?-300x225.webp)